In recent years, energy policies of developing countries face development of the use of biofuel. Modern production of biofuel and its combustion technologies enable effective use of practically all wood processing waste. In this regard, a growing number of construction projects of biofuel boiler-houses are being implemented in the country.

Technology of “Ekopartneris” biofuel boiler-house

Biofuel is flammable solid, liquid and gaseous products made of renewable energy (biomass) and is used to produce energy. There are large solid biofuel resources on the surface of Earth, such as timber, logging waste, straw, energy crops, grassland biomass, food industry waste and other renewable energy products.

Biofuel boiler-houses are designed to prepare high- and low-pressure steam and hot water. In practice, it may be subject to different technologies, depending on the selected boiler, its capacity and type of fuel that will be burned off.

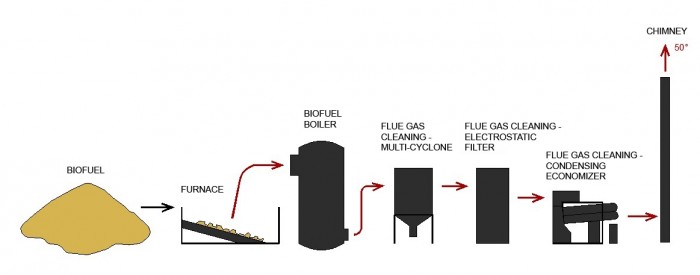

“Ekopartneris” is projecting a biofuel boiler-house where the use of solid biofuel is being planned. Main equipment of this biofuel boiler-house is fuel storage, dispersing to the furnace equipment, hot water boiler with a moving inclined grate furnace flue gas desulphurization and flue gas removal equipment, electrostatic filter, condensing economizer and chimney.

Scheme of a biofuel boiler-house with a condensing economizer

The main device in a biofuel boiler-house is water heating boiler, preparing and serving hot water to heating systems. Output of the boiler is controlled according to the temperature of water, outgoing from the boiler. The boiler is equipped with a fuel combustion chamber, where the combustion process is controlled by the quantity of oxygen in flue gas. In order to prevent corrosion of the metal surfaces of the boiler, temperature of flue gas should not be cooled below the dew point; therefore, efficiency of the boiler is up to 85-88%.

In order to increase the efficiency of biofuel boilers and heat extraction, condensing economizer is installed. Purpose of condensing economizer is to produce heat energy by using residual heat of flue gas that biofuel boilers exhaust. In economizer heat power is received both from physical and in the water vapor existing condensation heat. Exchange of heat proceeds immediately (flue gas – domestic hot water) in economizer itself, without intermediate heat exchangers. Temperature of flue gas is cooled below its dew point (from 250-150 °С to 50-65 °С), therefore, condensation heat is released, which accounts for 20-30% of the additional heat recovered in the boiler-house. As the wood used for biofuel boiler-houses are not dried, considerable amount of heat is lost to evaporate moisture, while in condensing economizer the heat is recovered and returned. In addition, through the condensing economizer transient flue gas is additionally cleaned from solids.

In the cleaning system of flue gas of “Ekopartneris” boiler-house will be a multi-cyclone, installed in two boilers. For collection of residual solids after the multi-cyclone will be installed an electrostatic filter whose working ranges will cover the entire operation range of the boiler-house. It should be noted that in the city of Kaunas the company will be the first to launch on its own initiative this technological device which is intended to reduce potential contamination and to fully comply with stringent EU pollution standards.